Animated LED Weddings Initials (WS2812B)

Animated LED Weddings Initials (WS2812B)

I recently got married and my girlfriend and I wanted to have our initial at the door of the reception hall but we also wanted them to be noticed. While they do sell premade letter with light in it, they were not only overly expensive for what they were but also not that pretty. It was either small incandescent lightbulb or very ugly white LED. I figured that I could do much better and set out to make our initials stand out!

My plan was to make use of WS2812b smart RGB LED which I recently started playing with. They are amazing, very cheap and easy to control. You can literally control hundreds of them with 3 wires only which make wiring them very straightforward. I started by buying wood letters to modify as I wanted to limit the amount of woodworking involved since I am not that used to that kind of work. Fortunately, I was lucky enough to find the perfect base letters to modify at Micheals, an art and craft supply store we have here in Canada. They were the perfect size and had a groove cut into them that made them exactly what I needed. My plan was to have the LEDs secured inside the groove and have it filled with epoxy resin. I also wanted the letters to match our wedding color theme which was coral and gold.

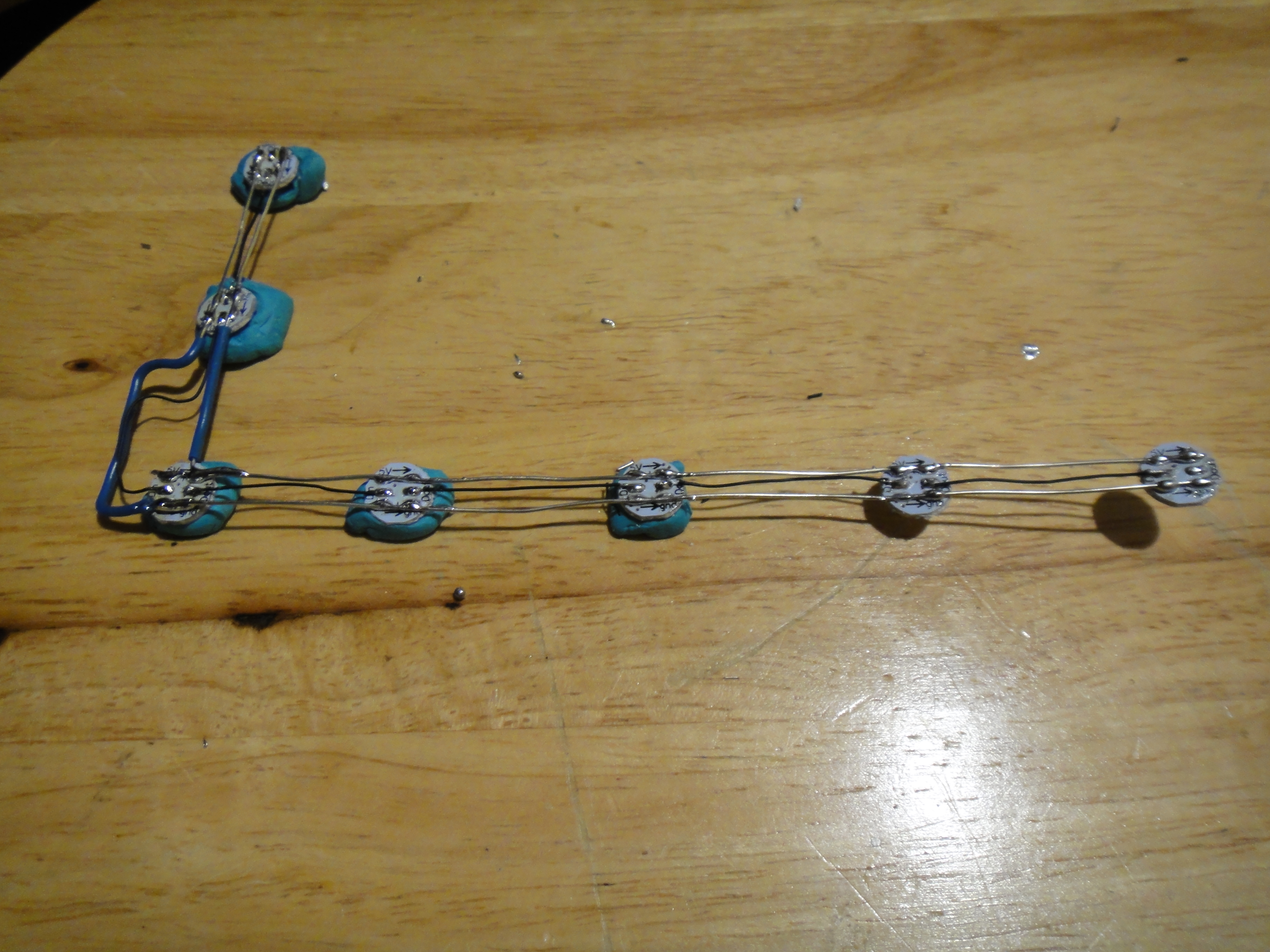

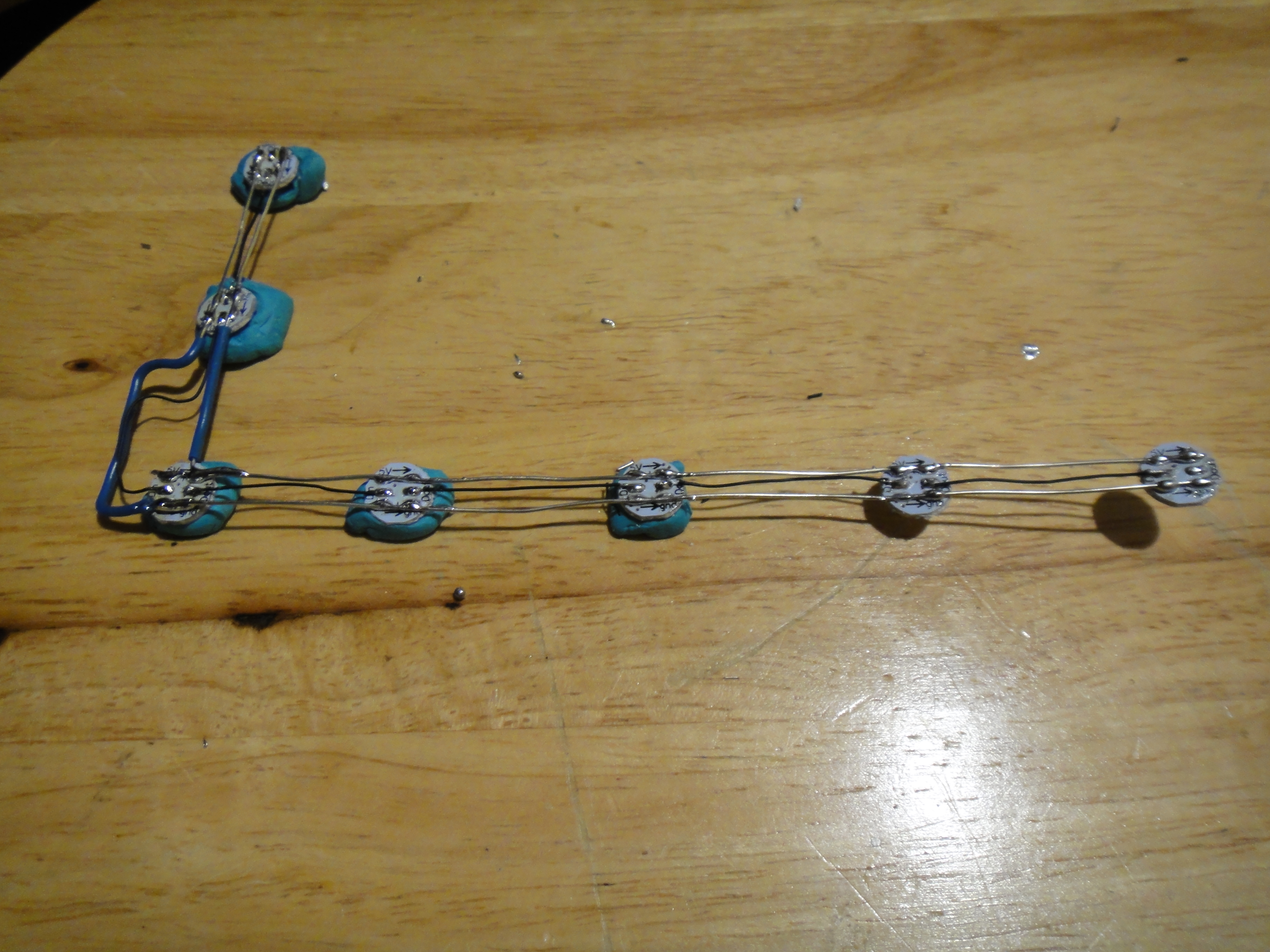

First, I needed to have the electronic side working before going any further, so I worked on getting the LED structure ready for each letter. To make sure the LED were evenly spaced in the letters groove, I put some blue tack gum to hold down the LED, measured and spaced the LED as to nicely fit inside the letter and started to solder a long strand of stripped wire along the voltage and the ground connection of each LED. This served two purposes, wire the power and ground connections of the LEDs and create a structure to hold the LEDs in the shape of the letter. I then soldered the data lines between each LEDs so that they could communicate with each other. You got to be careful as to make sure that you follow the directions written on the LEDs PCB because contrary to the power and ground line, you need to go from D-In to D-Out otherwise the LEDs won't light up properly or at all. You also can't just solder a big strand of stripped wire for the data lines.

Once they were all wires properly and I was satisfied with the placement of the LEDs, it was time to test them. I connected them to my Arduino using jumper wire and a breadboard and tested them with the normal strandtest from the Adafruit Neopixel Library. For those who are unaware, WS2812 LEDs and Adafruit's Neopixel are the same things, Adafruit just decided to give them a catchy name to market them on their store. Satisfied that the LEDs were communicating with each other and lighting up correctly, it was time to figure out what we wanted the LEDs to do. The easy route would have been to light them up a single color matching the wedding color theme but I wanted something a bit more dynamic. Of course I could have programmed something custom but my way of thinking on those thing is, why work on problems that are already solved. I had already decided on using the FastLEDs library instead of Adafruit's one as I prefer the way you program for it and found out about Palette Knife for FastLEDs. This is a very useful website that let you access the thousand color palette available at cpt-city and convert them to be easily used with the FastLEDs library. It would save me a whole lot of time and make the whole thing so much easier.

The way it work is, you go to the PaletteKnife website and save the special bookmark provided there. You then go to cpt-city and browse through the thousands of available color palettes submitted by users and chose one you like. Once you found something you'd like to try, you click on the PaletteKnife bookmark you added to your browser earlier and it will open a window with the FastLEDs code with the color value matching the pallet you have chosen. You then load up the Designer_Palettes example found in the FastLEDs library in the Arduino code editor and add your code. But the first thing to do is change the number next to the line #define NUM_LEDS to match the number of LEDs you will be using in your letter and make sure that your #define DATA_PIN match the output that you are using on your Arduino. Once that is done, you copy the code you got from the PaletteKnife bookmark and paste it under the section of code defining all the color palettes. Just spot the section with a bunch of block that start with ''DEFINE_GRADIENT_PALETTE( something_gp ) {'' and paste your palette code under one of those block.

Example palette code:

This work just like an index and we just added a new item to it. It will make your new palette available in the code and we now just need to have it called. To do this, you go the bottom of the code and look for a line that says ''const TProgmemRGBGradientPalettePtr gGradientPalettes[] = {''. Under this line, you will see things like bhw2_44_gp;Blue_Cyan_Yellow_gp etc... This work basically like a playlist and the name you see separated by a semicolon are the name of the palette defined in the previous section where we added our code. You add the name of the pallette you just defined to the rotation or delete all the other pallete name and only list your new palette so that it will just play your palette animation. You can now compile the code and upload it to your arduino. If all went well, you should see your LEDs light up and create a pleasing animation that will go through all the color of your pallete. If you have issues with LEDs not working, check to make sure that you have connected the LEDs data line to the correct arduino output as defined in your code and that you have defined the exact numbers of LEDs used. If your some LEDs light up and not other, check your wiring and make sure you followed from in, to out, to in etc... If some LEDs apear to be glitching and you have verified everything, it's possible one of your LEDs is defective. Try to replace it.

Everything was working perfectly and the palette I loaded had nice coral accent which matched our wedding color theme so I could now move on to the next step. I was fearing that we might see the wood texture on the end product so I painted my letters white as I wasn't sure yet how clear the epoxy would end up being and how I would decorate the letter later on. I cut a cloth hanger, bent the end like a hook and held them by the hole I made to later pass the LEDs wiring and used that to hold them up while I was spraypainting them outside.

Once they were dried and white enough for my taste, I put my LEDs wire structure inside the groove and secured them with a few spots of hot glue so that it wouldn't move once I would be pouring the resin. The letter is not painted because I took the picture before realizing I had not painted it yet:p

I had never worked with resin before so I went to read a bit but since I actually wanted to have bubbled in my mould, I didn't expect it to be too hard considering most of the work involved with resin moulding involve trying to avoid bubbles in your cast. I bought a gallon of Polyester Casting Resin and gave it a shot. It was a total failure, the mould never really set even after several days. I made a stupid mistake while mixing my resin and my catalyst and the proportion were way off. Also, this type of resin was not a good choice, it smells so strong and I had to rush it out of the house to try within 10 minutes because the smell was very bad. Even with the resin drying up outside of the house, it kept on smelling for days and this is a very unpleasant smell reminiscent of solvent and can give you quite the headache. I really would not recommend using that type of resin at home. Needless to say, I bought another kind of resin for my second take. This time I followed the advice of a friend that is used to do resin casting for cosplay and went with Pebeo Gedeo Crystal Resin. This is not cheap but it has the advantage of being much easier to use and does not smell anything so you can do it in your kitchen or basement and nobody will be bothered.

Since it is not so cheap (close to 20$ for 150 ml), I decided to do things properly and calculated how much I would need by measuring the groove's dimension and calculating the square inch footage of the surface to fill. This was a bit easier to do with the L letter. I broke the groove into two rectangles and measured the length, width and height and calculated the surface area of both rectangle with this formula.

Surface Area = 2(lw + lh + wh)

l= Length W=Width H=Height

I added up the surface area of both rectangle and then converted it to millilitres. It gave me the exact amount of resin needed to fill the groove. You could also just mix half of it and not bother with a mathematical formula:p I was worried that the LEDs would be too visible under the clear epoxy so I tried to add bubbles to the resin but failed. I also tried to make the resin less transparent hoping that the light source would not show as much. I researched a bit and see what I could use but considering I wanted it to be white, most of the stuff people use to dye epoxy wouldn't work so I improvised with what I had and tried powdered chalk. While it did work, a bit making the epoxy less transparent, it gave it a yellowish tint and getting rid of the little lump was harder than I expected.

You can see the letter filled with the resin/powdered chalk mix on the left and the leftover resin mixed with white spray paint on the right. Mixing the paint with the resin worked much better than I thought and it would have been even better if I didn't use the resin that I had mixed with chalk prior but the result was what I was trying to achieve.

I left the resin so harden during the night and it seems solid enough the next day to continue working on it. I made sure to test the LEDs again just to make sure they were still working because there was an issue with them not working well after my first failed casting attempt. They were lighting up as they should and it turned out really nice under the dyed white resin! You could still see a bit the source of the light but it was a bigger spot of light and you couldn't really see the LEDs or the wiring so it was good.

Now my original plan was to paint the letter white and then cut a stencil, apply glue and then apply the gold leave to the glue to make a intricate gold pattern and then seal everything under a layer of varnish. It would have been awesome but I somewhat ended up finishing them the night right before my wedding and I was running out of time so I had to come up with a new idea or we wouldn't be able to use them. My backup idea was to simply cover the letter completely with the gold leaves to give them an old-school look. I applied the gold leaves glue and let it dry for about 15 minutes. Once the glue felt tacky to the touch, I started gently pulling pieces of gold leaf and carefully applying them to the letter and rubbing the excess that would not stick.

In retrospective, it might have been easier to apply the leaves first and then pour the epoxy but it was too late. I was also rushing and didn't protect the resin with masking tape and a piece or two of gold got stuck in the middle of the resin so I worked with my mistake and added more to make it even. It ended up looking even better! You got to be really careful handling the gold leaves because they are unbelievably thin and will tear up and break at the slightest touch.

For a last-minute change of plan, I think it came out great!

Now it was time to fix the electronic and batteries to the back of the letter. For this you could use an arduino mini as they are very small and cheap and work just the same as a full-sized arduino. But since I like making my life complicated, I decided I would make the circuit really small and transfer the code directly to an ATTINY85 microcontroller. I won't go into too much detail for that part as there is plenty of tutorials online for that but it all comes down to installing the proper file in the arduino IDE (code editor) to make it recognize the tiny series of AVR, program the arduino bootloader to the chip and then upload your code to the attiny85 chip just like you would to a Arduino board. The attiny 45 and attiny85 are usually pretty much interchangeable but attiny45 would not work in this case because the designer palette code does not fit its memory, even after slimming down the code and removing every extra palette that you do not need.

I used one of those li-po battery charger that you can find all over eBay for super cheap..

Here's the finished result!

Twitter

(function(d, s, id) {

var js, fjs = d.getElementsByTagName(s)[0];

if (d.getElementById(id)) {return;}

js = d.createElement(s); js.id = id;

js.src = "//connect.facebook.net/en_GB/all.js#xfbml=1";

fjs.parentNode.insertBefore(js, fjs);

}(document, 'script', 'facebook-jssdk'));{lang: 'en-GB'}

I recently got married and my girlfriend and I wanted to have our initial at the door of the reception hall but we also wanted them to be noticed. While they do sell premade letter with light in it, they were not only overly expensive for what they were but also not that pretty. It was either small incandescent lightbulb or very ugly white LED. I figured that I could do much better and set out to make our initials stand out!

My plan was to make use of WS2812b smart RGB LED which I recently started playing with. They are amazing, very cheap and easy to control. You can literally control hundreds of them with 3 wires only which make wiring them very straightforward. I started by buying wood letters to modify as I wanted to limit the amount of woodworking involved since I am not that used to that kind of work. Fortunately, I was lucky enough to find the perfect base letters to modify at Micheals, an art and craft supply store we have here in Canada. They were the perfect size and had a groove cut into them that made them exactly what I needed. My plan was to have the LEDs secured inside the groove and have it filled with epoxy resin. I also wanted the letters to match our wedding color theme which was coral and gold.

First, I needed to have the electronic side working before going any further, so I worked on getting the LED structure ready for each letter. To make sure the LED were evenly spaced in the letters groove, I put some blue tack gum to hold down the LED, measured and spaced the LED as to nicely fit inside the letter and started to solder a long strand of stripped wire along the voltage and the ground connection of each LED. This served two purposes, wire the power and ground connections of the LEDs and create a structure to hold the LEDs in the shape of the letter. I then soldered the data lines between each LEDs so that they could communicate with each other. You got to be careful as to make sure that you follow the directions written on the LEDs PCB because contrary to the power and ground line, you need to go from D-In to D-Out otherwise the LEDs won't light up properly or at all. You also can't just solder a big strand of stripped wire for the data lines.

Once they were all wires properly and I was satisfied with the placement of the LEDs, it was time to test them. I connected them to my Arduino using jumper wire and a breadboard and tested them with the normal strandtest from the Adafruit Neopixel Library. For those who are unaware, WS2812 LEDs and Adafruit's Neopixel are the same things, Adafruit just decided to give them a catchy name to market them on their store. Satisfied that the LEDs were communicating with each other and lighting up correctly, it was time to figure out what we wanted the LEDs to do. The easy route would have been to light them up a single color matching the wedding color theme but I wanted something a bit more dynamic. Of course I could have programmed something custom but my way of thinking on those thing is, why work on problems that are already solved. I had already decided on using the FastLEDs library instead of Adafruit's one as I prefer the way you program for it and found out about Palette Knife for FastLEDs. This is a very useful website that let you access the thousand color palette available at cpt-city and convert them to be easily used with the FastLEDs library. It would save me a whole lot of time and make the whole thing so much easier.

The way it work is, you go to the PaletteKnife website and save the special bookmark provided there. You then go to cpt-city and browse through the thousands of available color palettes submitted by users and chose one you like. Once you found something you'd like to try, you click on the PaletteKnife bookmark you added to your browser earlier and it will open a window with the FastLEDs code with the color value matching the pallet you have chosen. You then load up the Designer_Palettes example found in the FastLEDs library in the Arduino code editor and add your code. But the first thing to do is change the number next to the line #define NUM_LEDS to match the number of LEDs you will be using in your letter and make sure that your #define DATA_PIN match the output that you are using on your Arduino. Once that is done, you copy the code you got from the PaletteKnife bookmark and paste it under the section of code defining all the color palettes. Just spot the section with a bunch of block that start with ''DEFINE_GRADIENT_PALETTE( something_gp ) {'' and paste your palette code under one of those block.

Example palette code:

This work just like an index and we just added a new item to it. It will make your new palette available in the code and we now just need to have it called. To do this, you go the bottom of the code and look for a line that says ''const TProgmemRGBGradientPalettePtr gGradientPalettes[] = {''. Under this line, you will see things like bhw2_44_gp;Blue_Cyan_Yellow_gp etc... This work basically like a playlist and the name you see separated by a semicolon are the name of the palette defined in the previous section where we added our code. You add the name of the pallette you just defined to the rotation or delete all the other pallete name and only list your new palette so that it will just play your palette animation. You can now compile the code and upload it to your arduino. If all went well, you should see your LEDs light up and create a pleasing animation that will go through all the color of your pallete. If you have issues with LEDs not working, check to make sure that you have connected the LEDs data line to the correct arduino output as defined in your code and that you have defined the exact numbers of LEDs used. If your some LEDs light up and not other, check your wiring and make sure you followed from in, to out, to in etc... If some LEDs apear to be glitching and you have verified everything, it's possible one of your LEDs is defective. Try to replace it.

Everything was working perfectly and the palette I loaded had nice coral accent which matched our wedding color theme so I could now move on to the next step. I was fearing that we might see the wood texture on the end product so I painted my letters white as I wasn't sure yet how clear the epoxy would end up being and how I would decorate the letter later on. I cut a cloth hanger, bent the end like a hook and held them by the hole I made to later pass the LEDs wiring and used that to hold them up while I was spraypainting them outside.

Once they were dried and white enough for my taste, I put my LEDs wire structure inside the groove and secured them with a few spots of hot glue so that it wouldn't move once I would be pouring the resin. The letter is not painted because I took the picture before realizing I had not painted it yet:p

I had never worked with resin before so I went to read a bit but since I actually wanted to have bubbled in my mould, I didn't expect it to be too hard considering most of the work involved with resin moulding involve trying to avoid bubbles in your cast. I bought a gallon of Polyester Casting Resin and gave it a shot. It was a total failure, the mould never really set even after several days. I made a stupid mistake while mixing my resin and my catalyst and the proportion were way off. Also, this type of resin was not a good choice, it smells so strong and I had to rush it out of the house to try within 10 minutes because the smell was very bad. Even with the resin drying up outside of the house, it kept on smelling for days and this is a very unpleasant smell reminiscent of solvent and can give you quite the headache. I really would not recommend using that type of resin at home. Needless to say, I bought another kind of resin for my second take. This time I followed the advice of a friend that is used to do resin casting for cosplay and went with Pebeo Gedeo Crystal Resin. This is not cheap but it has the advantage of being much easier to use and does not smell anything so you can do it in your kitchen or basement and nobody will be bothered.

Since it is not so cheap (close to 20$ for 150 ml), I decided to do things properly and calculated how much I would need by measuring the groove's dimension and calculating the square inch footage of the surface to fill. This was a bit easier to do with the L letter. I broke the groove into two rectangles and measured the length, width and height and calculated the surface area of both rectangle with this formula.

Surface Area = 2(lw + lh + wh)

l= Length W=Width H=Height

I added up the surface area of both rectangle and then converted it to millilitres. It gave me the exact amount of resin needed to fill the groove. You could also just mix half of it and not bother with a mathematical formula:p I was worried that the LEDs would be too visible under the clear epoxy so I tried to add bubbles to the resin but failed. I also tried to make the resin less transparent hoping that the light source would not show as much. I researched a bit and see what I could use but considering I wanted it to be white, most of the stuff people use to dye epoxy wouldn't work so I improvised with what I had and tried powdered chalk. While it did work, a bit making the epoxy less transparent, it gave it a yellowish tint and getting rid of the little lump was harder than I expected.

You can see the letter filled with the resin/powdered chalk mix on the left and the leftover resin mixed with white spray paint on the right. Mixing the paint with the resin worked much better than I thought and it would have been even better if I didn't use the resin that I had mixed with chalk prior but the result was what I was trying to achieve.

I left the resin so harden during the night and it seems solid enough the next day to continue working on it. I made sure to test the LEDs again just to make sure they were still working because there was an issue with them not working well after my first failed casting attempt. They were lighting up as they should and it turned out really nice under the dyed white resin! You could still see a bit the source of the light but it was a bigger spot of light and you couldn't really see the LEDs or the wiring so it was good.

Now my original plan was to paint the letter white and then cut a stencil, apply glue and then apply the gold leave to the glue to make a intricate gold pattern and then seal everything under a layer of varnish. It would have been awesome but I somewhat ended up finishing them the night right before my wedding and I was running out of time so I had to come up with a new idea or we wouldn't be able to use them. My backup idea was to simply cover the letter completely with the gold leaves to give them an old-school look. I applied the gold leaves glue and let it dry for about 15 minutes. Once the glue felt tacky to the touch, I started gently pulling pieces of gold leaf and carefully applying them to the letter and rubbing the excess that would not stick.

In retrospective, it might have been easier to apply the leaves first and then pour the epoxy but it was too late. I was also rushing and didn't protect the resin with masking tape and a piece or two of gold got stuck in the middle of the resin so I worked with my mistake and added more to make it even. It ended up looking even better! You got to be really careful handling the gold leaves because they are unbelievably thin and will tear up and break at the slightest touch.

For a last-minute change of plan, I think it came out great!

Now it was time to fix the electronic and batteries to the back of the letter. For this you could use an arduino mini as they are very small and cheap and work just the same as a full-sized arduino. But since I like making my life complicated, I decided I would make the circuit really small and transfer the code directly to an ATTINY85 microcontroller. I won't go into too much detail for that part as there is plenty of tutorials online for that but it all comes down to installing the proper file in the arduino IDE (code editor) to make it recognize the tiny series of AVR, program the arduino bootloader to the chip and then upload your code to the attiny85 chip just like you would to a Arduino board. The attiny 45 and attiny85 are usually pretty much interchangeable but attiny45 would not work in this case because the designer palette code does not fit its memory, even after slimming down the code and removing every extra palette that you do not need.

I used one of those li-po battery charger that you can find all over eBay for super cheap..

Here's the finished result!

Twitter

(function(d, s, id) {

var js, fjs = d.getElementsByTagName(s)[0];

if (d.getElementById(id)) {return;}

js = d.createElement(s); js.id = id;

js.src = "//connect.facebook.net/en_GB/all.js#xfbml=1";

fjs.parentNode.insertBefore(js, fjs);

}(document, 'script', 'facebook-jssdk'));{lang: 'en-GB'}

60 out of

100 with

1 ratings

I recently got married and my girlfriend and I wanted to have our initial at the door of the reception hall but we also wanted them to be noticed. While they do sell premade letter with light in it, they were not only overly expensive for what they were but also not that pretty. It was either small incandescent lightbulb or very ugly white LED. I figured that I could do much better and set out to make our initials stand out!

My plan was to make use of WS2812b smart RGB LED which I recently started playing with. They are amazing, very cheap and easy to control. You can literally control hundreds of them with 3 wires only which make wiring them very straightforward. I started by buying wood letters to modify as I wanted to limit the amount of woodworking involved since I am not that used to that kind of work. Fortunately, I was lucky enough to find the perfect base letters to modify at Micheals, an art and craft supply store we have here in Canada. They were the perfect size and had a groove cut into them that made them exactly what I needed. My plan was to have the LEDs secured inside the groove and have it filled with epoxy resin. I also wanted the letters to match our wedding color theme which was coral and gold.

First, I needed to have the electronic side working before going any further, so I worked on getting the LED structure ready for each letter. To make sure the LED were evenly spaced in the letters groove, I put some blue tack gum to hold down the LED, measured and spaced the LED as to nicely fit inside the letter and started to solder a long strand of stripped wire along the voltage and the ground connection of each LED. This served two purposes, wire the power and ground connections of the LEDs and create a structure to hold the LEDs in the shape of the letter. I then soldered the data lines between each LEDs so that they could communicate with each other. You got to be careful as to make sure that you follow the directions written on the LEDs PCB because contrary to the power and ground line, you need to go from D-In to D-Out otherwise the LEDs won't light up properly or at all. You also can't just solder a big strand of stripped wire for the data lines.

Once they were all wires properly and I was satisfied with the placement of the LEDs, it was time to test them. I connected them to my Arduino using jumper wire and a breadboard and tested them with the normal strandtest from the Adafruit Neopixel Library. For those who are unaware, WS2812 LEDs and Adafruit's Neopixel are the same things, Adafruit just decided to give them a catchy name to market them on their store. Satisfied that the LEDs were communicating with each other and lighting up correctly, it was time to figure out what we wanted the LEDs to do. The easy route would have been to light them up a single color matching the wedding color theme but I wanted something a bit more dynamic. Of course I could have programmed something custom but my way of thinking on those thing is, why work on problems that are already solved. I had already decided on using the FastLEDs library instead of Adafruit's one as I prefer the way you program for it and found out about Palette Knife for FastLEDs. This is a very useful website that let you access the thousand color palette available at cpt-city and convert them to be easily used with the FastLEDs library. It would save me a whole lot of time and make the whole thing so much easier.

The way it work is, you go to the PaletteKnife website and save the special bookmark provided there. You then go to cpt-city and browse through the thousands of available color palettes submitted by users and chose one you like. Once you found something you'd like to try, you click on the PaletteKnife bookmark you added to your browser earlier and it will open a window with the FastLEDs code with the color value matching the pallet you have chosen. You then load up the Designer_Palettes example found in the FastLEDs library in the Arduino code editor and add your code. But the first thing to do is change the number next to the line #define NUM_LEDS to match the number of LEDs you will be using in your letter and make sure that your #define DATA_PIN match the output that you are using on your Arduino. Once that is done, you copy the code you got from the PaletteKnife bookmark and paste it under the section of code defining all the color palettes. Just spot the section with a bunch of block that start with ''DEFINE_GRADIENT_PALETTE( something_gp ) {'' and paste your palette code under one of those block.

Example palette code:

This work just like an index and we just added a new item to it. It will make your new palette available in the code and we now just need to have it called. To do this, you go the bottom of the code and look for a line that says ''const TProgmemRGBGradientPalettePtr gGradientPalettes[] = {''. Under this line, you will see things like bhw2_44_gp;Blue_Cyan_Yellow_gp etc... This work basically like a playlist and the name you see separated by a semicolon are the name of the palette defined in the previous section where we added our code. You add the name of the pallette you just defined to the rotation or delete all the other pallete name and only list your new palette so that it will just play your palette animation. You can now compile the code and upload it to your arduino. If all went well, you should see your LEDs light up and create a pleasing animation that will go through all the color of your pallete. If you have issues with LEDs not working, check to make sure that you have connected the LEDs data line to the correct arduino output as defined in your code and that you have defined the exact numbers of LEDs used. If your some LEDs light up and not other, check your wiring and make sure you followed from in, to out, to in etc... If some LEDs apear to be glitching and you have verified everything, it's possible one of your LEDs is defective. Try to replace it.

Everything was working perfectly and the palette I loaded had nice coral accent which matched our wedding color theme so I could now move on to the next step. I was fearing that we might see the wood texture on the end product so I painted my letters white as I wasn't sure yet how clear the epoxy would end up being and how I would decorate the letter later on. I cut a cloth hanger, bent the end like a hook and held them by the hole I made to later pass the LEDs wiring and used that to hold them up while I was spraypainting them outside.

Once they were dried and white enough for my taste, I put my LEDs wire structure inside the groove and secured them with a few spots of hot glue so that it wouldn't move once I would be pouring the resin. The letter is not painted because I took the picture before realizing I had not painted it yet:p

I had never worked with resin before so I went to read a bit but since I actually wanted to have bubbled in my mould, I didn't expect it to be too hard considering most of the work involved with resin moulding involve trying to avoid bubbles in your cast. I bought a gallon of Polyester Casting Resin and gave it a shot. It was a total failure, the mould never really set even after several days. I made a stupid mistake while mixing my resin and my catalyst and the proportion were way off. Also, this type of resin was not a good choice, it smells so strong and I had to rush it out of the house to try within 10 minutes because the smell was very bad. Even with the resin drying up outside of the house, it kept on smelling for days and this is a very unpleasant smell reminiscent of solvent and can give you quite the headache. I really would not recommend using that type of resin at home. Needless to say, I bought another kind of resin for my second take. This time I followed the advice of a friend that is used to do resin casting for cosplay and went with Pebeo Gedeo Crystal Resin. This is not cheap but it has the advantage of being much easier to use and does not smell anything so you can do it in your kitchen or basement and nobody will be bothered.

Since it is not so cheap (close to 20$ for 150 ml), I decided to do things properly and calculated how much I would need by measuring the groove's dimension and calculating the square inch footage of the surface to fill. This was a bit easier to do with the L letter. I broke the groove into two rectangles and measured the length, width and height and calculated the surface area of both rectangle with this formula.

Surface Area = 2(lw + lh + wh)

l= Length W=Width H=Height

I added up the surface area of both rectangle and then converted it to millilitres. It gave me the exact amount of resin needed to fill the groove. You could also just mix half of it and not bother with a mathematical formula:p I was worried that the LEDs would be too visible under the clear epoxy so I tried to add bubbles to the resin but failed. I also tried to make the resin less transparent hoping that the light source would not show as much. I researched a bit and see what I could use but considering I wanted it to be white, most of the stuff people use to dye epoxy wouldn't work so I improvised with what I had and tried powdered chalk. While it did work, a bit making the epoxy less transparent, it gave it a yellowish tint and getting rid of the little lump was harder than I expected.

You can see the letter filled with the resin/powdered chalk mix on the left and the leftover resin mixed with white spray paint on the right. Mixing the paint with the resin worked much better than I thought and it would have been even better if I didn't use the resin that I had mixed with chalk prior but the result was what I was trying to achieve.

I left the resin so harden during the night and it seems solid enough the next day to continue working on it. I made sure to test the LEDs again just to make sure they were still working because there was an issue with them not working well after my first failed casting attempt. They were lighting up as they should and it turned out really nice under the dyed white resin! You could still see a bit the source of the light but it was a bigger spot of light and you couldn't really see the LEDs or the wiring so it was good.

Now my original plan was to paint the letter white and then cut a stencil, apply glue and then apply the gold leave to the glue to make a intricate gold pattern and then seal everything under a layer of varnish. It would have been awesome but I somewhat ended up finishing them the night right before my wedding and I was running out of time so I had to come up with a new idea or we wouldn't be able to use them. My backup idea was to simply cover the letter completely with the gold leaves to give them an old-school look. I applied the gold leaves glue and let it dry for about 15 minutes. Once the glue felt tacky to the touch, I started gently pulling pieces of gold leaf and carefully applying them to the letter and rubbing the excess that would not stick.

In retrospective, it might have been easier to apply the leaves first and then pour the epoxy but it was too late. I was also rushing and didn't protect the resin with masking tape and a piece or two of gold got stuck in the middle of the resin so I worked with my mistake and added more to make it even. It ended up looking even better! You got to be really careful handling the gold leaves because they are unbelievably thin and will tear up and break at the slightest touch.

For a last-minute change of plan, I think it came out great!

Now it was time to fix the electronic and batteries to the back of the letter. For this you could use an arduino mini as they are very small and cheap and work just the same as a full-sized arduino. But since I like making my life complicated, I decided I would make the circuit really small and transfer the code directly to an ATTINY85 microcontroller. I won't go into too much detail for that part as there is plenty of tutorials online for that but it all comes down to installing the proper file in the arduino IDE (code editor) to make it recognize the tiny series of AVR, program the arduino bootloader to the chip and then upload your code to the attiny85 chip just like you would to a Arduino board. The attiny 45 and attiny85 are usually pretty much interchangeable but attiny45 would not work in this case because the designer palette code does not fit its memory, even after slimming down the code and removing every extra palette that you do not need.

I used one of those li-po battery charger that you can find all over eBay for super cheap..

Here's the finished result!